At its heart, Maryland Thermoform’s business is all about heating a sheet of plastic, draping it over a mold and allowing it to cool for various customer design needs. But it’s much more than that. Technologically, it gets more complicated than molding plastic sheeting.

At its heart, Maryland Thermoform’s business is all about heating a sheet of plastic, draping it over a mold and allowing it to cool for various customer design needs. But it’s much more than that. Technologically, it gets more complicated than molding plastic sheeting.

“Thermoforming is a very creative process. It’s kind of like a black art,” said Scott Macdonald, CEO of Maryland Thermoform.

The process can be very symmetrical or very artsy.

“You can develop products with your hands or machinery. It can look as if you made it by hand, and to me that’s very cool,” Macdonald said.

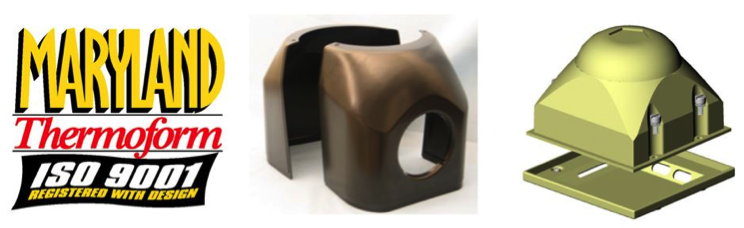

Thermoforming takes shape in many creative forms and sizes. Part design must account for not only aesthetics, but must consider technical aspects such as draw ratio, wall thickness, rigidity and strength. Secondary operations such as trimming, decorating and assembly are often performed. Some products and packaging are very closely toleranced – the art becomes a very exact science.

“We pride ourselves on customization,” said Maryland Thermoform President Jim Hall.

Maryland Thermoform serves a variety of industries including cosmetics, food packaging, aerospace and medical. They’ve created specialized packaging for various industries and products, including unmanned aircraft, undersea vehicles, cosmetic packaging, disposable noodle trays, and many other applications.

While they can’t publicly discuss some defense industry work, some of the work includes electrostatic dissipated packaging for electronic components and sub assemblies for unmanned aircraft.

So, what sets this company apart? Continue to read more about its innovation and energy-reduction efforts by visiting RMIenergysolutions.com.